A log sheet template Excel is really easy to edit. All you really have to do is download the right template. After downloading, you need to be able insert all the details that are relevant or necessary. You can write down the purpose you’re using it for, and the time, which. EYEWASH STATION INSPECTION CHECKLIST BENEFITS Workers’ eyes are vulnerable to various hazards on the job, such as dust, pieces of material shooting out of equipment and splashes of hazardous substances. Although you should take steps to protect workers from getting anything in their eyes, something could still happen.

When working with corrosives, drenching facilities must be readily available. The Occupational Safety and Health Administration’s (OSHA) Medical and First Aid Standard 29 Code of Federal Regulations (CFR) 1910.151(c) states, “Where the eyes or body of any person may be exposed to injurious corrosive materials, suitable facilities for quick drenching or flushing of the eyes and body shall be provided within the work area for immediate emergency use.”

SMT Inspection Templates: Inspection templates enhance the visual inspection process by guiding the operator's eyes to a specific location on the board to check for the presence and correctness of components. StenTech’s pin support templates are manufactured from a clear acrylic material to allow for a rigid template.

These drenching facilities could include an eyewash, eye/face wash, shower or combination eye/face wash shower depending on the amount of possible exposure. Because OSHA does not clarify what the minimum requirements for “suitable facilities” are, employers often look to the voluntary American National Standards Institute (ANSI) Z358.1-2014 Standard for Emergency Eyewashes and Shower Equipment for guidance. ANSI Z358.1-2014 helps users select and install proper emergency equipment to meet OSHA requirements. Also, OSHA often uses ANSI Z358.1 as a guide during inspections and may elect to issue penalties based on non-compliance.

Emergency eyewashes and showers often go unused. Blackberry 9780 os 7 download. It’s important to test these devices regularly to help ensure they will function properly in an emergency. Studies show that the seconds immediately following an eye injury or chemical splash are often critical to minimizing damage.

To ensure that eyewash stations and showers are always ready when needed, it is important that the requirements for test procedures and maintenance set forth in Z358.1-2014 be followed.

The requirements for testing and maintaining eye, eye/face washes and showers are based on the manufacturer’s instructions and ANSI protocols. Generally, the manufacturer’s instructions state that the devices should be inspected, tested and the results recorded weekly. Individual owners’ manuals should be looked at for the specific manufacturer's guidelines.

ANSI Z358.1-2014 is divided into five sections and each section addresses minimum performance and use requirements, as well as installation, testing procedures, maintenance and training requirements.

ANSI Z358.1-2014 Plumbed and Self-Contained Emergency Showers, Eyewash Equipment, Eye/Face Wash Equipment and Combination Units Performance and Maintenance Criteria:

- Must be designed, manufactured and installed in such a manner that, once activated, they can be used without requiring the use of the operator’s hands

- Valve must easily activate in a second or less, remain open on its own until it is intentionally turned off and be resistant to corrosion

- If shut off valves are installed in the supply line for maintenance purposes, provisions must be made to prevent unauthorized shut off

- If a potential for freezing exists, product specifically designed to avoid freezing should be used

- Plumbed units must be activated on a weekly basis long enough to ensure that flushing fluid is provided

- Plumbed and self-contained showers must maintain a minimum flushing fluid of 20 gallons per minute (GPM) at 30 pounds per square inch (PSI) for a minimum of 15 minutes

- Plumbed and Self-Contained Eyewash Equipment must maintain a minimum flushing fluid of 0.4 GPM at 30 psi for 15 minutes

- Eye/Face wash equipment must maintain a minimum flushing fluid of 3 GPM at 30 PSI for 15 minutes

- Determine that flushing fluid is tepid (between 60 – 100°F) and in circumstances where chemical reactions are accelerated by flushing fluid temperature, a facilities safety/health advisor should be consulted for the optimum temperature for each application

- Determine that flushing fluid is dispersed throughout the required pattern

- Showers, eyewashes, eye/face washes, and drench hoses all can be utilized in combination units and the requirements of each of these types of product categories must be met when utilized with other categories of emergency equipment

- Self-contained units must be visually checked weekly to determine if the flushing fluid needs to be changed or supplemented in accordance with the manufacturer’s instructions.

- Supplemental equipment is intended for immediate use and must be followed up by the usage of emergency product that can provide a minimum of 15 minutes of flushing fluid continuously

- Personal eyewash units and drench hoses are considered supplemental equipment

Each year emergency products must be inspected to ensure they comply with the ANSI standard. While a fixture may be certified to meet the ANSI standard before it is installed, once installed, it is important to make sure it is installed according to the standard's requirements. You can also use a weekly checklist (below) to help ensure the proper operation of a unit in an emergency.

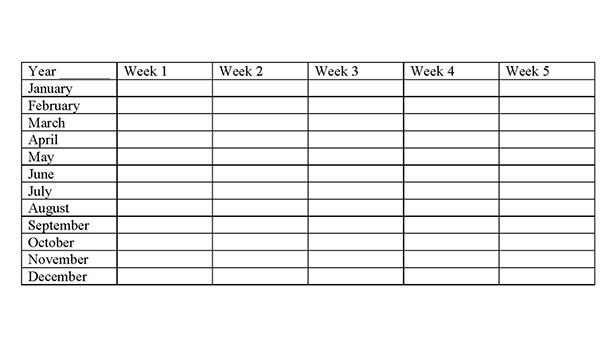

Weekly Checklist

- Initial and date in the corresponding box verifying that the emergency eyewash / shower is checked weekly to ensure:

- Equipment installed within 10 seconds from the hazard and on the same plane as the hazard

- Pathway is clear of obstructions

- Plumbed equipment activated to ensure compliant operation and to clear any sediment

- Self-contained equipment checked to determine if the flushing fluid needs to be changed or supplemented

- Equipment free of broken or missing parts

- Equipment protected against freezing

- User protected from scalding water

| Year ____ | Week 1 | Week 2 | Week 3 | Week 4 | Week 5 |

| January | |||||

| February | |||||

| March | |||||

| April | |||||

| May | |||||

| June | |||||

| July | |||||

| August | |||||

| September | |||||

| October | |||||

| November | |||||

| December |

Always inspect and test emergency eyewashes and showers if you have any doubt about their dependability. Identify problems or concerns and establish a regular maintenance program. Consult the manufacturers’ operating manual and ANSI Z358.1-2014 for assistance with test procedures, maintenance operations and training.

Q. Who should be trained on the proper use of emergency eyewashes and showers?

A. ANSI Z358.1-2014 states that employees who may be exposed to hazardous materials must be trained on the use of eyewash and shower devices. Specific areas that should be addressed include the location of the units, how to properly activate the systems and how to correctly maintain the devices.

Q. Are there any recommended procedures on how to effectively flush eyes that have been contaminated?

A. Individuals should be instructed to hold the eyelids open and roll the eyeballs so fluid will flow on all surfaces of the eye and under the eyelid.

Q. Are there any alternatives to the frequent changing of gravity-fed eyewash solutions?

A. Yes. Factory-sealed cartridges containing eyewash solutions are available. These products have shelf lives well in excess of preservative solutions and are significantly easier to maintain.

Sources

ANSI/ISEA Z358.1-2014

American National Standards Institute

11 W. 42nd Street

New York, NY 10036

212.642.4900

www.ansi.org

(Rev. 3/2015)

Find even more information you can use to help make informed decisions about the regulatory issues you face in your workplace every day. View all Quick Tips Technical Resources at www.grainger.com/quicktips.

Think Safety. Think Grainger.®

Grainger has the products, services and resources to help keep employees safe and healthy while operating safer facilities. You’ll also find a network of safety resources that help you stay in compliance and protect employees from hazardous situations. Count on Grainger for lockout tagout, fall protection equipment, confined space products, safety signs, personal protective equipment (PPE), emergency response and so much more!

Please Note:

The information contained in this publication is intended for general information purposes only and is based on information available as of the initial date of publication. No representation is made that the information or references are complete or remain current. This publication is not a substitute for review of the current applicable government regulations and standards specific to your location and business activity, and should not be construed as legal advice or opinion. Readers with specific questions should refer to the applicable standards or consult with an attorney.

Eyewash Station Inspection Tag Printable

©2018 W.W. Grainger, Inc.